How Wall Panel Forming Machines Can Help You Achieve Faster and More Efficient Production

Introduction

Wall panel forming machines are an essential tool for the construction industry. They are used to create high-quality wall panels that are strong, durable, and efficient. These machines have revolutionized the way wall panels are produced, making the process faster, more efficient, and cost-effective. In this article, we will discuss how wall panel forming machines can help you achieve faster and more efficient production.

What are Wall Panel Forming Machines?

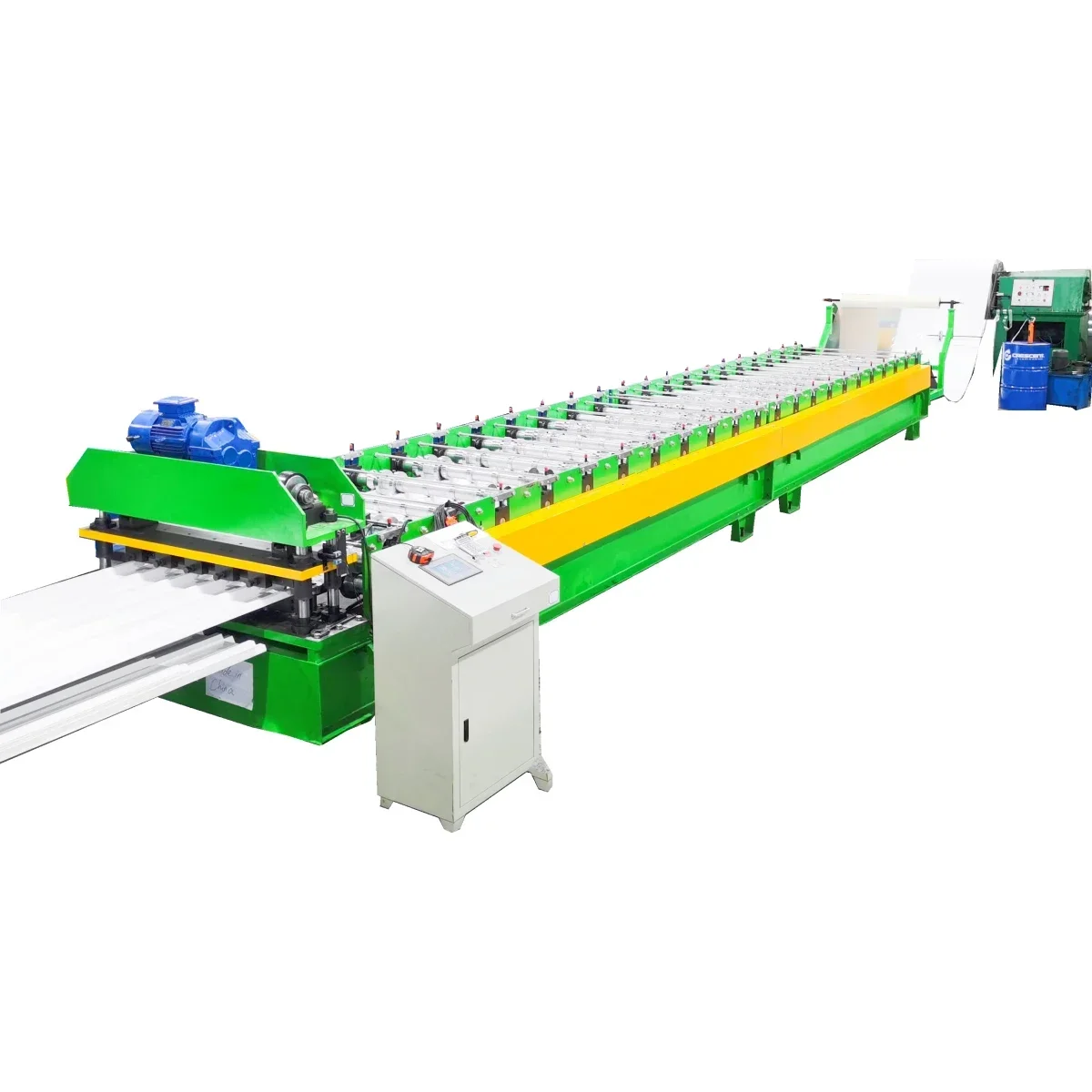

Wall panel forming machines are machines that are used to create wall panels. They are designed to produce panels of various sizes and shapes, depending on the requirements of the project. These machines are used to create panels made of different materials, including steel, aluminum, and other metals. They are also used to create panels made of composite materials, such as fiber cement, gypsum, and other materials.

How Wall Panel Forming Machines Work

Wall panel forming machines work by feeding the material into the machine, which then shapes and forms the material into the desired shape. The machine uses a series of rollers and dies to shape the material into the desired shape. The machine can be programmed to create panels of different sizes and shapes, depending on the requirements of the project.

Advantages of Wall Panel Forming Machines

There are several advantages of using wall panel forming machines. These include:

1. Faster More Efficient Production

Wall panel forming machines can produce panels at a much faster rate than traditional methods. This is because the machines are automated, which means that they can work continuously without the need for breaks or rest periods. This results in faster production times, which can help to reduce project timelines and increase productivity.

Wall panel forming machines are also more efficient than traditional methods. This is because they require less manual labor, which means that fewer workers are needed to operate the machines. This results in lower labor costs and increased efficiency.

2. Consistent Quality

Wall panel forming machines are designed to produce panels of consistent quality. This is because the machines are programmed to create panels of the same size and shape every time. This results in panels that are uniform in size and shape, which can help to improve the overall quality of the project.

Conclusion

Wall panel forming machines are an essential tool for the construction industry. They are designed to produce high-quality wall panels that are strong, durable, and efficient. These machines have revolutionized the way wall panels are produced, making the process faster, more efficient, and cost-effective. If you are looking to improve your production process, consider investing in a wall panel forming machine.