Products

Cross Beam Roll Forming MC

Manufacturer: | Wuxi LonGar | Quotation: | 2023-02-21 | |

MC Name: | Cross Beam MC | MC Color : | White +Yellow (Customized ) | |

Power:: | 380V 50Hz 3Ph(or Customized) | HIM language: | Chinese -English(or Customized) | |

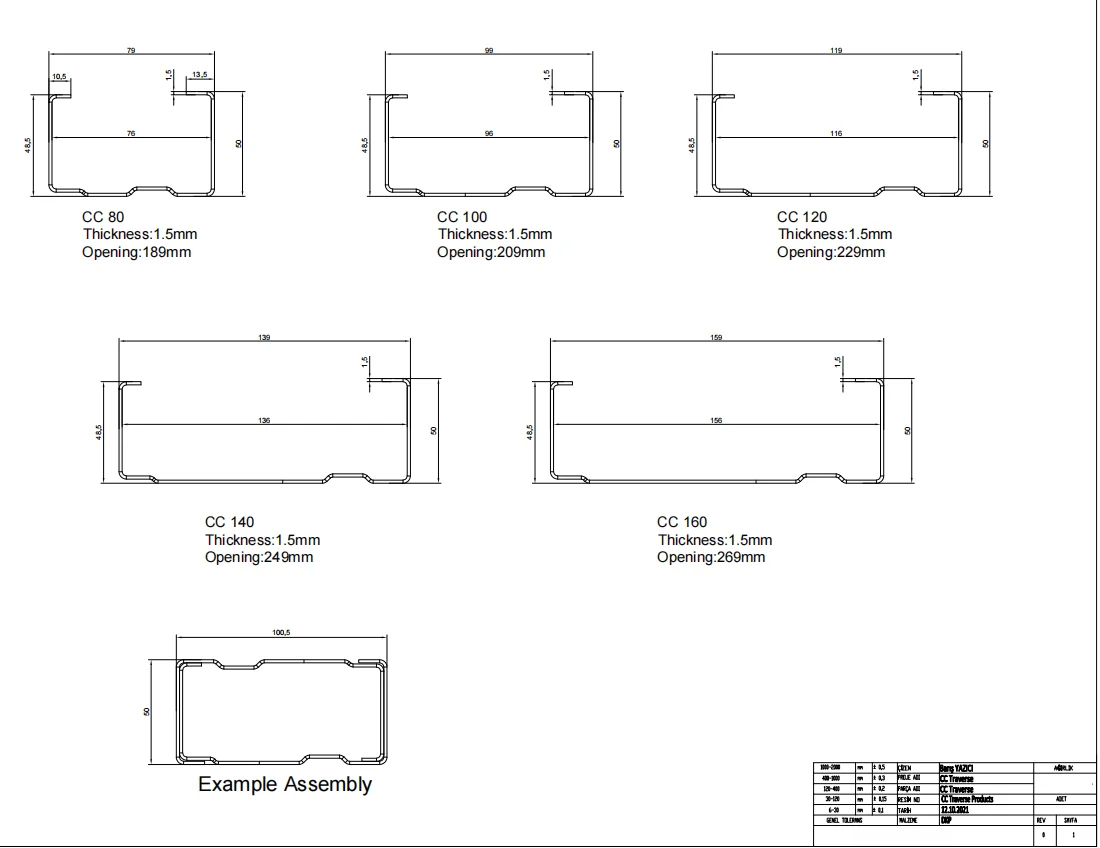

Profile |

| |||

Raw material | Raw materials: (Q235B) Pay attention to raw materials! Thickness: 1.2-1.5mm Tolerance: length ± 1mm width height ± 0.5mm (The goods shall be inspected according to the fixed thickness, and the customer shall provide local materials) | |||

Detailed description of machine components | ||||

Flow chart : | Manual uncoiling - feeding guide - leveling - forming machine - hydraulic rear shear - conveying turnover table - occluding forming machine - discharging table | |||

| ||||

Un-coiler | # Manual tensioning, driven by molding machine # Load capacity: 5 tons # Coil ID: φ 508mm # Inner tightening size range: φ 460-520 mm |

| ||

Guider &Leveler | # Set at the beginning of the host to help the operator adjust the direction of the feeding plate correctly. The left side and the right side can be adjusted respectively through the handwheel # 7 leveling roller(3+4),up 3 and down 4 # Leveling roller material: 40Cr, chrome plated # Assembled on the molding machine # Leveling motor: 5.5kw #Diameter of leveling roller: φ 80mm |

| ||

Forming MC: | # Molding machine form: archway chain drive # Roller table form: the roller table on both sides is split, and the main shaft is inserted # Roll material: Cr12, finish machining after quenching # Shaft material: high-quality 45 # steel quenched and tempered # Main shaft diameter: 60/80mm # Bearing: φ 65 (Harbin Bearing) # Main motor power: 15KW # Transverse motor power: 1X1.5KW #ØRoller station: 16 (including correction) Forming speed: 0-15m/min, excluding punching |

| ||

Hydraulic fly saw cutter: | # Working mode: hydraulic shearing, non-stop shearing # Servo motor: 2.9kw, Yaskawa # Thickness waste: no waste # Raw material of scissors: Cr12Mov, SKD11, HRC >62 ° # Number of knives: 4 knives (different specifications of knives) # Length encoder brand: KOYO (Japan) Ø# The maximum shear length is 6 meters |

| ||

Conveying table : | # Conveying roller table structure: roller structure, section steel welding, automatic conveying #Transmission mode: chain transmission # Motor power: 2.2kw × 3 # Platform size: designed according to the maximum # Length : 6 meters # Platform function: with rollover |

| ||

Embracing Occlusal MC | # Body structure: arch structure # Forming motor: 5.5kw # After the bottom width is set on the touch screen, it will automatically traverse through the motor # Transmission mode: chain structure, 1.5 inches # Roller station: 5 # Wheel material: GCr15 # Shaft diameter: 80mm # Forming speed: 0-15m/min, regulated by Yaskawa frequency converter # Bite synthesis machine has a separate control cabinet |

| ||

Hydraulic station | # Hydraulic power: 7.5kw #Solenoid valve: Beijing Huade # Hydraulic valve: Beijing Huade # The hydraulic station is equipped with an air cooling device |

| ||

Output table | #2m*2 Simple and unpowered (angle steel welding, drum stripping) |

| ||

Electrical cabinet : | # PLC: Siemens # Operation mode: manual and automatic switchable # Touch screen(HIM): MCGS # Frequency converter: Yaskawa # Encoder: Koya # Aviation plug is used for convenient wiring |

| ||

Related Products